DFOS Sensor Cables for Harsh Environments

Unlock the full potential of Distributed Fiber Optic Sensing (DFOS) with Neubrex's rugged, high-accuracy sensor cables – engineered for strain, temperature, and acoustic measurement across critical infrastructure, geotechnical systems, boreholes, and more.

Why Choose Neubrex Cables?

Neubrex cables integrate cutting-edge fiber optic technology with robust materials and advanced calibration, delivering long-term reliability and precision in real-world applications.

Key Benefits:

- Compatible with BOTDA, BOTDR, TW-COTDR, and DTS technologies

- Built-in temperature compensation (depending on model)

- Engineered for harsh environments: chemical, thermal, and UV resistance

- Factory calibrated for ultra-precise NEUBRESCOPE performance

-

Ideal for embedding in concrete, mounting to steel, or borehole deployment

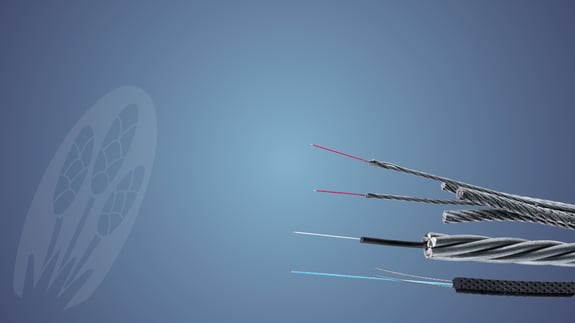

Meet the EMBOSS Cable Series

EMBOSS Cables are designed for reliable fiber optic sensing in demanding conditions. With rugged embossed sheaths, dual singlemode fibers, and high tensile strength, they ensure strong adhesion and precise measurements — whether embedded in concrete, mounted on rebar, or installed in boreholes.

FN-SSL-3 FiberTape – Fast, Flexible, and Easy to Apply

The FN-SSL-3 is a flexible, surface-mounted fiber sensor for strain and temperature monitoring. With two single-mode fibers in a thin tape format, it easily adheres to curved or flat surfaces. Just peel and press — no embedding or special tools needed.

It offers reliable performance from -40°C to +80°C, with strong adhesion and quick setup in under 24 hours.

Optimized for Concrete Integration and Long-Term Monitoring

FN-SILL-3 delivers accurate strain and temperature data in reinforced concrete. Its embossed sheath ensures strong bonding, while high UV and heat resistance enable durable, long-term performance.

Your Questions About Fiber Sensing — Answered

GIPS (galvanized iron-plated steel) provides solid protection at a lower cost and is well-suited for standard industrial use. SUS304 stainless steel offers higher corrosion resistance, making it ideal for marine, chemical, or high-moisture environments.

Single-mode fibers (used in EBSS models) are optimal for long-range sensing and higher precision. Multi-mode fibers (used in EBSM models) support shorter-range applications and allow for broader data transmission.

Yes. Models like FN-SILL-3 and FiberTape are designed for seamless integration into concrete or composite structures, ensuring strong bonding and long-term durability in construction monitoring.

The best cable depends on both your sensing needs and the physical environment in which it will be installed.

If your project requires a strong, cost-effective cable for general industrial use, a GIPS-armored model is a reliable choice. It provides solid mechanical protection and performs well in most standard conditions.

If your installation environment involves exposure to saltwater, moisture, or corrosive chemicals — such as in tunnels, coastal areas, or chemical plants — it’s better to use a stainless steel (SUS304) armored model, which offers superior corrosion resistance and long-term reliability.

For the type of fiber:

-

Use EBSS cables if your sensing system relies solely on single-mode fiber, which is often used for long-range, high-precision applications.

-

Choose EBSM cables if you need to support both single-mode and multi-mode fibers in one cable — ideal for more complex or flexible sensing setups.

If you're embedding fiber directly into concrete or composite structures, such as bridges, slabs, or tunnels, go with FN-SILL-3 or FiberTape. These specialized cables are designed for strong bonding with concrete and long-term durability under pressure, heat, and environmental stress.

In short: choose based on your environment (corrosive or standard) and your technical setup (fiber type and integration needs).

Still have questions? We're here to help.

Whether you’re looking for more technical details or need advice on choosing the right product — our team is happy to support you.